This year I want to work more efficiently with my hand tools.

That doesn’t necessarily mean I want to work faster, but I do want to make better use of my time at the workbench. I do want to work faster in certain circumstances, but efficiency is about more than just speed. It’s about making the most of the time and materials I have available to me.

Here are some principles that I think can make me a more efficient woodworker:

Practice the fundamentals. Every project requires me to saw straight and square, plane to gauge lines, and chisel straight. Frequent work keeps me in practice.

Do rough work with aggressive tools, and leave fine work for fine tools. Back when I had only a smoothing plane, stock preparation was slow and aggravating. Now I have a jack plane that takes shavings at least 1/16” thick. I got a coarse crosscut saw and a coarser rip saw for breaking down stock. Sometimes I remember to use a hatchet or drawknife instead of a saw to remove the edge of a board.

Do rough work with aggressive tools, and leave fine work for fine tools. Back when I had only a smoothing plane, stock preparation was slow and aggravating. Now I have a jack plane that takes shavings at least 1/16” thick. I got a coarse crosscut saw and a coarser rip saw for breaking down stock. Sometimes I remember to use a hatchet or drawknife instead of a saw to remove the edge of a board.

Choose wood for workability. Cherry, red oak, and walnut aren’t favored only for their appearance. They are also relatively easy to work. While you can make your drawer fronts out of kiln-dried hickory or hard maple, you will find the softer hardwoods easier to handle. When I’m working with home-center pine, I buy enough that I can cut around the knots. There is much to be said for building with clear pine.

Leave hidden areas rough. While it is good to know how to four-square a board, it is seldom necessary. I’m learning to leave the undersides of panels rough-sawn. I don’t fill gaps in joints that will be hidden. And I never finish the insides or undersides of casework.

Simplify layout. I want to work to gauge lines and divider marks as much as possible. I recently realized I could cut one part to length and then use it to determine the lengths of matching pieces instead of measuring each piece separately. Sometimes efficiency is as simple as reducing the chances of calculation errors, which are big time-wasters in my shop.

Use machines judiciously. As I have integrated electric machines into my woodworking, I have learned that they do not automatically make me more efficient. Each machine takes time to set up, and that set-up time often more than offsets the speed at which the machine can do its work. And the machine leaves a rough surface that must usually be cleaned up afterward. I am learning to predict when a machine will speed me up and when it will slow me down.

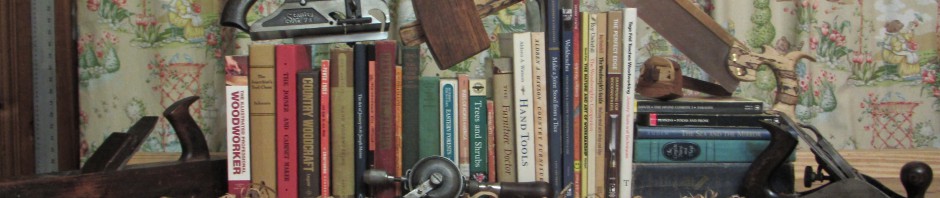

Keep a clear bench. By the end of a project my bench is often covered with tools that haven’t been used for hours, and I can’t find the tool I need. Take a tool out, use it, and then put it away. My new tool chest is making it easier to do this, but I need to exercise more self-discipline in getting tools put away promptly.

Keep a clear bench. By the end of a project my bench is often covered with tools that haven’t been used for hours, and I can’t find the tool I need. Take a tool out, use it, and then put it away. My new tool chest is making it easier to do this, but I need to exercise more self-discipline in getting tools put away promptly.

A lot of hobby woodworkers don’t care much about the speed of their work. Some work in high-pressure environments all day and have no interest in speeding up workflow at home. Others merely enjoy the process too much to worry about efficiency. There is something to be said for taking your time.

However, there are good reasons to work efficiently. If you are working under a deadline, the reason is obvious: to finish on time. But even when you are working on your own timetable, you should practice working efficiently so that you are able to complete a project quickly when you need to. Besides, inefficient work is frustrating, and if you work inefficiently enough, you will be tempted to abandon a project altogether.

Most importantly, time is a resource like any other. We are given a limited amount of it, and it deserves to be used well and not wasted. Profligate waste of a gift is an insult to the giver.

Totally agree with your comments. In addition clean. I clean all shavings/ sawdust that are produced from either hand tools or machine tools as I create them. Keep your attention so that you have all actions planned out and move smoothly from one operation to the next. Sometimes I stop and assess so assess twice and cut once. Glue up is my biggest challenge so I have to keep studying articles to help me in this area. Take pratice cuts before cutting the real piece. Sharpen planes and chisels often. I wear a shop apron so that all my pencils measure instruments etc. are handy.

Great post, I spent hours cleaning up and organizing my shop recently, something that was long overdue. My shop is still in the development stages and until I build all of my storage needs it tends to get cluttered quickly but for now it’s improved quite a bit. I’m starting to realize the benefits of keeping a clear bench and shop, the frustration that comes from having to clear my bench just to lay down a piece I’m working on far greater then the little bit of effort it takes to keep things neat and tidy. Well done!

Very well put. I tend to find that a cluttered workshop and / or bench is what slows me down the most. The problem is, that sometimes it is necessary to work on more projects at one time.

Being an efficient woodworker is an admirable goal.

Happy New Year