How big is the ideal workshop?

Just a little bit bigger than the one you have.

We don’t like to work within strict limitations, especially not those measured in square feet. Yet most amateur woodworkers have to make do with relatively small shop spaces, many of which are set up inefficiently or haphazardly.

There are many ways to conserve space in a small shop. Here are some I have used successfully:

1. Go Vertical. Use your wall space and even your ceiling space for storage. Install shallow cabinets for hand tools and hardware and wall racks for clamps. You can store lumber in wall racks or even hang it from the ceiling, which I’ve seen done effectively in garage shops. You haven’t really filled your shop until the walls are full, too.

1. Go Vertical. Use your wall space and even your ceiling space for storage. Install shallow cabinets for hand tools and hardware and wall racks for clamps. You can store lumber in wall racks or even hang it from the ceiling, which I’ve seen done effectively in garage shops. You haven’t really filled your shop until the walls are full, too.

2. Get Rolling. I’m not fond of big machines on wheels. The casters raise some of the work surfaces a little too far above a comfortable working height for me. And locking casters are seldom as stable as a machine standing directly on the floor. Nonetheless, being able to pull out a drill press and then push it back into its corner is a major space-saver. Collapsible or multipurpose out-feed tables help, too.

3. Go Outside. Patios, driveways, and porches offer big spaces, natural lighting, and good airflow. Just sweep or rake away the chips and shavings when you’re done. Don’t have space for a dedicated assembly table? Use a picnic table. Don’t have space in your shop for a chop-saw station? Set up a temporary one outside with a couple sawhorses for workpiece support. In the summer time or during rain, you could put up a canopy under which to work. Do your finishing on the patio or on the porch–you could even build yourself a collapsible spray booth out of tarps and PVC pipe. I do all my finishing outdoors where fumes are minimal and sunlight enriches the natural colors of many woods.

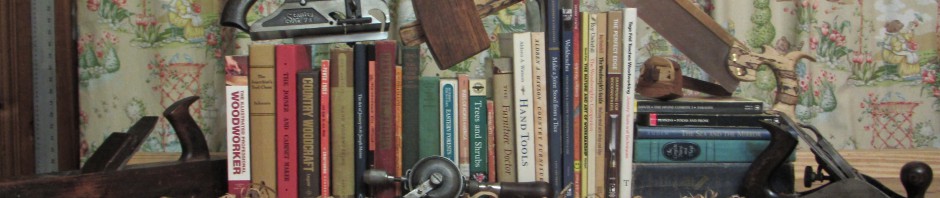

4. Use Your Hand Tools. If you learn to saw accurately by hand, you will find that some machines and many jigs are unnecessary. If you learn to joint boards by hand, then you can forgo a powered jointer but keep the thickness planer. Plus you can work with boards of any width without having to work within the limitations of a powered jointer. If you do your joinery by hand and get a good bandsaw, even the table saw becomes optional. A dovetail saw takes up less cabinet space than a dovetail router jig. A large set of molding planes takes up less space than a router table. A mortise chisel takes up less floor space than a mortising machine. Most of my tools fit into a single tool chest, which rolls under one end of the workbench. The rest are stored in two wall-mounted racks. So long as you don’t start collecting hand tools, they’re quite the space-saver.

4. Use Your Hand Tools. If you learn to saw accurately by hand, you will find that some machines and many jigs are unnecessary. If you learn to joint boards by hand, then you can forgo a powered jointer but keep the thickness planer. Plus you can work with boards of any width without having to work within the limitations of a powered jointer. If you do your joinery by hand and get a good bandsaw, even the table saw becomes optional. A dovetail saw takes up less cabinet space than a dovetail router jig. A large set of molding planes takes up less space than a router table. A mortise chisel takes up less floor space than a mortising machine. Most of my tools fit into a single tool chest, which rolls under one end of the workbench. The rest are stored in two wall-mounted racks. So long as you don’t start collecting hand tools, they’re quite the space-saver.

5. Set an Acquisition Limit. Every woodworking magazine and website touts the newest, most improved, must-have tool that we didn’t know we needed until we read the glowing product review. But your shop space is limited. It limits the number and size of tools you can acquire. Do not buy a new tool that you cannot store or use in a convenient location. If you absolutely must have a tool you don’t have room for, then make space by selling or giving away non-essential tools. Focus on equipping your shop with the most versatile, high-quality tools you can get and learn to use them effectively.

The acquisitive spirit is the enemy of craft. Nobody has ever made anything out of wood by wishing he had a bigger shop in which to work. The best way–indeed, the only way–to work in a small space is to just go work in it.

Love it! Especially the Acquisition Limit. Hard to do, but good information.

Thanks. I’ve had to be pretty severe with myself about new tool acquisitions, but the trade-off is that I usually have space to work at my bench. It’s liberating, really, to get out of the consumerist hamster wheel.

Stack up those walls! I also have hooks everywhere! I also have most everything on casters, and pull things out into a work alley that has a clearance eight feet of clearance on both sides, and depending on the machine up to eight feet in width, most machines don’t need that much space, my router table only needs two feet deep of space and if I need more, I roll it out a bit more. I’m mot quite up to the ceiling yet, I have some hooks installed but I don’t like the idea of loosing headroom, my garage is in the basement, so I’m already limited height wise. I like your rule about acquisition limits also. Stuff only ends up collecting dust because there is so much you can’t keep track! So what’s the point of owning it if you never use it!

A collapsable spray booth? Going to have to look that one up 🙂

It’s just an idea I came up with. Hang up a few cheap shower curtains from the porch rafters or on a PVC pipe frame and throw something up on top. As long as the wind isn’t strong, there’s no reason it shouldn’t work.