Not long ago, I picked up an old hand-cranked grinder, and I have been slowly learning to use it. (I can’t find a manufacturer’s name anywhere.) I had been using an ancient belt sander for assorted grinding tasks, but it was loud and rickety, so when it finally choked to death on its own dust, I was excited to try out a real grinder.

Putting the grinder to use posed some initial difficulties, even before I could put steel to the wheel.

Challenge #1: Finding the Right Wheel

The new, super-cool wheels for high-speed grinders have received much praise. I had my eye on a blue wheel from Norton until I realized that the smallest diameter wheel Norton makes is 6″ and my grinder can fit up to a 5″ wheel. I finally found a 5″ gray wheel at McMaster-Carr, though I was disappointed that the maximum width they carried was 3/4″. My grinder could fit a 1″-wide wheel. I got the 60-grit, which is plenty aggressive for my purposes. I also found that the arbor on my grinder is 3/8″ in diameter, whereas the bushings that come with the wheel only go down to 1/2″. I got an additional nylon bushing, too, and now the wheel fits snugly.

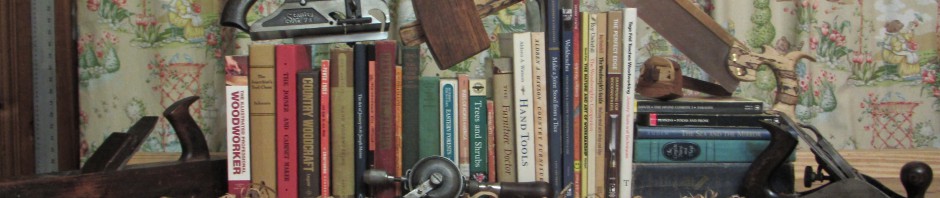

The grinder is attached to a scrap of 2X8 lumber, which is then clamped to the front of the bench. It is reasonably stable, but I would like to build a more permanent mount for it, perhaps something with an integral tool rest.

Challenge #2: Coordination

Once the grinder is equipped with a good wheel, the greatest challenge is getting used to cranking with one hand while holding the tool with the other. On the advice of an acquaintance, I oriented the grinder as above. I stand facing the crank. Not only is it easier to move the tool back and forth across the wheel, but it is also easier to see what’s going on at the contact point.

You can’t beat being able to see the edge contacting the stone. This makes it easy to eyeball an appropriate bevel angle.

This setup is especially convenient because it renders the grinder portable. Most of the time it will stay right here, but if it gets in the way of another project, I can quickly remove it. If I liked, could clamp it to a sawhorse in the back yard and grind tool edges while my children play on the swing-set.

Challenge #3: Uneven Spinning

The concentric bushings that came with the wheel fit snugly enough, and I had to coax the extra bushing into place with a couple mallet taps, but no matter how carefully you mount the wheel, it will always be a little off-center. That’s why a wheel dresser is necessary. I got a diamond wheel dresser from Lee Valley, and it works very well.

I quickly learned that when dressing your wheel, you should always wear a dust mask and eye protection! Dust and chips go flying everywhere. I hadn’t thought about putting on my safety glasses while using this grinder because of the direction the grinder is mounted to the bench. It’s doesn’t usually throw debris into my face. Nevertheless, bits of the wheel can go flying in any direction, so safety gear is always warranted.

Challenge #4: Overheating

Can you blue an edge with a hand-cranked grinder? I’m not sure, and I don’t intend to find out. (“Bluing” an edge occurs when the steel heats up so much on the grinder that it turns blue and loses its hardness, thus ruining the tool’s ability to hold a cutting edge.) The steel does get pretty hot when I turn the crank quickly, so when the steel gets too hot to hold bare-handed, I dunk it in a coffee can of cold water for a couple seconds.

A 1/2″ chisel I was practicing on. It doesn’t take long to grind a proper bevel. With care and regular honing, the bevel on this chisel may never need to be re-ground again.

Smaller chisels are easier to grind than larger ones. It took me quite a while to establish a consistent bevel on the 2″-wide chisel I picked up at an antique store last month. The 60-grit wheel doesn’t cut very quickly, and that’s just fine with me. Until I get better at using a hand-cranked grinder, I’m going to stay away from the lower, more aggressive grits.

Challenge #5: Dirty Windows

Unlike a regular high-speed grinder, there is no housing to help contain sharpening debris.

I had no idea how far the grinder was throwing debris until I looked up from my work.

I must remember to keep a bottle of Windex near my new sharpening station.

I have an old Carborundum Co. ‘Black Knight’ which looks very similar to yours and also has a 3/8 in arbor.

With the wheel clamped to end of a wider board and applying the chisel at around 9-o-clock I find most of the swarf ends up on the board – I’m surprised it’s going up your window like that. What kind of rpm are you turning at? Are you turning clockwise or anti-clockwise?

I couldn’t even guess at the RPM, but I’m turning the crank pretty briskly. You can probably guess from the photos that I’m grinding with the wheel spinning away from the edge, so clockwise if you like. It’s all a result of my placing the tool near the top of the wheel. If I turned the crank in the other direction, then the debris would end up on the ground, but also on my left hand.

Ah, that explains it. I think it’s usual to place the tool lower on the wheel and rotate clockwise, that is with the wheel spinning towards the edge.

Wonderful things, these old hand-cranked grinding wheels!

They are, indeed.

I tried spinning the wheel in both directions, and I found I could hold the workpiece more securely with the wheel spinning away from the edge. I’m not exactly sure why.

A friend of mine just informed me that Norton DOES make a 5″ wheel, which is available here:

http://www.amazonsupply.com/dp/B004L2LHBE/ref=sp_dp_g2c_asin

Once I wear down my current wheel a bit, I’ll have to give this one a try and report back. Thanks, Michael!

Where did you find the proper bushing/adapter for the small arbor? I have a White Knight with a 3/8th arbor on the way via ebay.

Thanks for sharing these tips!

They’re just nylon bushings from McMaster-Carr. They came as a set of several sizes, and I ordered them along with the wheel.