One of the biggest enemies of hand tools is rust, and what with the humidity in my region, I have to be extra-careful with rust prevention. I have found that taking several precautions keeps the rust off my tools.

1. Keep the Dust Off.

When dust accumulates on your tools, moisture from the air can easily condense around the dust particles, which in turn begins to rust your tools. When you put tools away, wipe the dust off. If possible, contain your tools in a cabinet or toolbox. But don’t leave the door/lid open when you work! Otherwise the dust in your shop will settle on your tools.

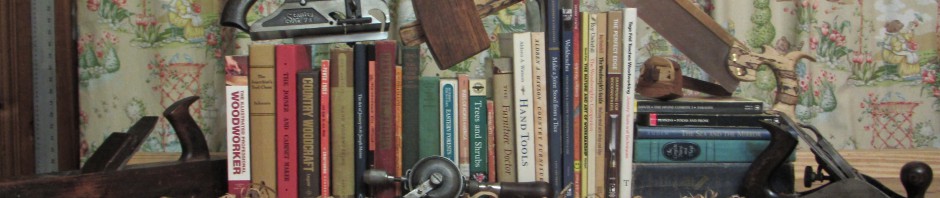

Putting seldom-used tools into separate containers, such as plane socks, bags, or other containers, can also prevent rust. For serious rust risks (e.g. a toolbox stored in a garage), small dehumidification devices are available commercially. I have not tried them, but I am told by several acquaintances that they work well.

2. Coat Your Tools with a Rust Preventer.

You can use any number of substances to lay down a protective layer between bare metal and moisture in the air. I wax the soles of my planes with paraffin, and I have successfully used Top-Cote, sold in a spray-can, for other plane parts. Traditionally, joiners used mutton tallow, which works fine but eventually goes rancid. Fully-synthetic engine oil will also work. Many woodworkers today like to use camellia oil.

Lately, I’ve been using jojoba oil, which is similar to camellia oil but significantly less expensive at my local health-food store, where it’s sold as a body oil.

I apply it with this little device:

Yes, a tomato paste can with a rolled up T-shirt stuffed inside. I drizzle the oil on top, let it soak in, and then run it over my planes, chisels, and layout tools. Once the cloth is saturated, I need only invert the can, and the oil seeps back to the surface. It needs just a little refreshing from time to time.

The idea is not mine, though. I got it from Paul Sellers when I took a joinery class with him at the Homestead Heritage School of Woodworking.

3. Use Your Tools Frequently.

Although taking tools in and out of a toolbox or cabinet can expose them to dust and moisture, it also gives you a chance to examine your tools for early signs of rust or corrosion. I also suspect that the friction of plane soles and chisel backs against the wood helps wear off tiny rust spots just as they are beginning to form. I have learned from experience that my tools are most at risk for rust when they sit idle for months at a time.

Pingback: Jojoba Oil For Tools: 17 Amazing Benefits - The Oil Virtue