This is the final installment of my bed frame build-along. The first four episodes are here (#1), here (#2), here (#3), and here (#4).

I kept plunking away at the project, but opportunities for good photos became rarer. I bought the pine 2X4s I needed to build the undercarriage on which the box spring will sit. Each cherry side rail will have a 2X4 screwed to the inside, which will both add considerable rigidity and give the box spring a ledge to rest on. There will be six stretchers run across the width of the bed frame too, in order to support the box spring all around, as well as to keep the frame nice and square.

I had to do some digging in the pile at Lowes to find the right boards. The sides had to be dead straight, or close enough that my hand planes could handle the job without much trouble. The stretchers, though, didn’t require as much pickyness. (My spellchecker informs me that “pickyness” is not a word. Well, what does it know?) I intentionally selected some 2X4s that had a little bow in them.  The bow will face up on the finished project, and the weight of the mattress should push the boards back down flat. That’s the theory, anyway.

The bow will face up on the finished project, and the weight of the mattress should push the boards back down flat. That’s the theory, anyway.

So this evening I cut notches in the side pieces to receive the stretchers.

I clamped them together so I could be sure the notches lined up exactly. The bottoms of the notches are well beyond the reach of my small router plane, and not having a large router plane, I had to make do with a broad chisel. They came out all right, though.

Then came time to cut the tenons on the ends of the long side pieces. They’re over 80″ long, so cutting tenons on the ends was a wee bit awkward.  (Still less awkward than trying to cut this joint using a table saw, though.) The best I could do was this.

(Still less awkward than trying to cut this joint using a table saw, though.) The best I could do was this.

Stick it in the vise at an angle, and get up over it with the tenon saw. I ended up standing with one foot on a chair and the other foot on the bench to finish the cuts. It worked out fine, though.

You get a nice shot of my ugly tenon saw, there. It’s an old Warranted Superior that I remember abusing on the farm when I was growing up. It helped build a couple tree forts, though, and I’m amazed it survived. I eventually salvaged it from my parents’ house out of sheer pity (and because I needed a backsaw), sharpened it up, and put it to use. It took a while to get it working right, but it cuts very well now.

The next day, I finished the whole project. (Gory details ahead–not for the faint-of-heart!)

Once the foot board was done, I decided to take one more measurement so I could get the side rails lined up with the head board.  The head board allows for 59 1/2″ between the rails. But what have we here?!

The head board allows for 59 1/2″ between the rails. But what have we here?!

How on earth did I get this thing 1/2″ too short?!!

(I used that emoticon a lot when I built this thing.)

I took a deep breath and considered my options. I didn’t want to try to re-build the foot board. For one, I haven’t enough wide, straight boards left. For another, I’m running out of time before school starts.

That’s No Ordinary Rabbet!

I went back to measure the box spring. It looked like I could just squeeze it into a 59 1/4″ space. Hmmmm. I needed to buy myself 1/4″, or 1/8″ on each side. I decided on my course of action.

Each side rail would get a really wide rabbet, just over 1/8″ deep but over 3″ wide. Now, my rabbet plane (fence missing) is only 1 1/2″ wide, so that won’t work.  My plow plane fence has a max depth of only 2″ or so. That is, with the fence on the normal side. But with the fence attached from the other side, the capacity is over 3″! Bingo! I used gauges to mark my rabbet and started plowing a 3/8 groove left-handed.

My plow plane fence has a max depth of only 2″ or so. That is, with the fence on the normal side. But with the fence attached from the other side, the capacity is over 3″! Bingo! I used gauges to mark my rabbet and started plowing a 3/8 groove left-handed.

Then out came the rough planes, to start hogging out the waste.

(My apologies for the fuzzy picture, but I was in a big hurry at this point.)

With a bench plane tilted into the groove, I was able to use the groove as a natural fence, beveling off the edge of the groove on the waste side. That left me a generous portion on the edge to hog off as best I could with the bench planes. Yeah, I had to go through the tenons too. Oh well. I can patch it up with wedges later. For once in my life, I wished I had a table saw with a dado stack.

Finally, I was ready to fit the rails into the foot board mortises. These were drawbored too, and they fit pretty well when dry-fitted. So I stuck them together as best I could and tried to let the drawbore pegs do the rest. But no luck! The pegs went right through without closing up the gap at the shoulder at all!

Another  , but not so intense as the last one.

, but not so intense as the last one.

I’ve had about 50/50 success with drawboring so far. I wonder if the pecan pegs are too flexible? Or too narrow? Next time I’ll go for the full 1/4″ and offset the holes further.

I’ve had about 50/50 success with drawboring so far. I wonder if the pecan pegs are too flexible? Or too narrow? Next time I’ll go for the full 1/4″ and offset the holes further.

At any rate, after a liberal dose of home-made wood putty, I put together the undercarriage frame.

That was by far the easiest part. Notches and screws. I used 48 screws in assembling the whole thing, so it’s pretty tight. (Yes, I counted. Plus, I bought a box of 50 wood screws, and there were two left over.)

Stopped Chamfers

I wanted the lines on this bed frame to be clean and simple, but not “modern.” I was going for something more “Shaker” in appearance–that is, if the Shakers would have made queen-sized beds. I considered a short taper on the legs, but that didn’t seem quite right for this piece. I settled on stopped chamfers, which I cut with a chisel and a spokeshave.

I began by marking the depth of the chamfer with a pencil, and marking the width of the chamfer with a marking gauge.

I then started the cut by making a notch at an angle with the chisel, bevel-down. I followed that by using a mallet and chisel, still bevel-down, to knock out most of the waste. I worked almost down to my layout lines.

I used the spokeshave to cut right down to the lines, and as soon as the lines disappeared, I was done.

If you look very closely, you’ll see that some of them are a little irregular, but who looks that closely? I did this on both the top and the bottom of each of the four legs, so there is symmetry throughout the piece.

Finish Him!

I used three coats of the traditional home-brew: 1 part each mineral spirits, varnish (polyurethane), and boiled linseed oil. It worked like a charm and buffed out to a nice, even sheen that still looks more like wood than like plastic (my objection to some top-coats). The finish is wet in the picture below, but the boiled linseed oil really makes the curly figure in the panels stand out.

I brushed on each coat at 15-minute intervals, being sure to saturate any end-grain. This was especially important at the tops and bottoms of each panel, since the bevels expose a lot of end-grain. I allowed the final coat to dry for about 30 minutes. Then, using a clean, lint-free cloth, I buffed the whole surface vigorously until it was smooth.

I brushed on each coat at 15-minute intervals, being sure to saturate any end-grain. This was especially important at the tops and bottoms of each panel, since the bevels expose a lot of end-grain. I allowed the final coat to dry for about 30 minutes. Then, using a clean, lint-free cloth, I buffed the whole surface vigorously until it was smooth.

Any finish containing boiled linseed oil will occasionally bleed-out. That is, tiny amounts of the oil may sometimes leak back out of the wood after buffing, leaving little beads on the surface. If you get them in time, you can just buff them out again. I like to check my Danish-oiled finishes every hour or so for a few hours for bleed-out, and re-buff when necessary. That gives me time to sit down for a while and read a book between buffing sessions, and the extra buffing imparts a shine to the piece that’s deep but not glossy.

I assembled it the next afternoon when the smell of the finish had mostly subsided. Although I had to gently coax the box spring in with a rubber mallet, it just fit.

The room is too dark to give you a good idea of the wood’s color now that the finish is dry, but you get a sense of it. Yes, the carpet in my bedroom really is that color. No, I am not responsible for it. Yes, we are planning on replacing it soon.

I did not time myself, but I estimate that I have a good 45 or 50 hours of work in this bed frame. In use, the frame is solid and does not creek or squeak in use.

And I have a nice place to sleep now.

This is beautiful! Woodwork is something I would love to explore, but I typically picture making simple toys – the bed is inspiring.

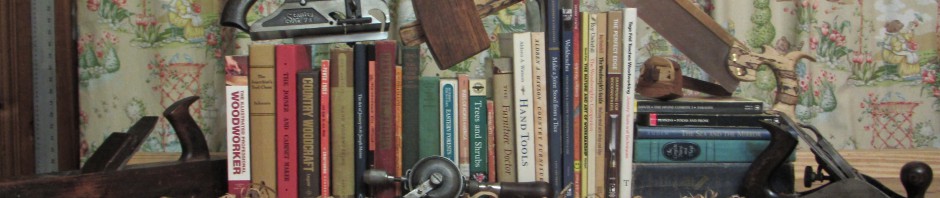

Thanks, Emily. I certainly didn’t start working wood with these kinds of projects, even though I’ve only been doing this for about five years. One of these days I’m going to put together a blog post of my early work. I started with simple items, especially bookshelves, which I found were pretty easy to make with a few simple tools and some (very) basic skills. I hope you’ll explore woodworking eventually.

Pingback: Timber Framed Bunk Beds, part 4: Mostly Finished | The Literary Workshop Blog